Offset Printing – Processes, Types, and Advantages

Offset printing, otherwise called offset lithography, is a widely used printing technique in large-scale commercial printing enterprises. The technique involves transferring (or offsetting) the inked image or design from the metal plate it is etched to a rubber cylindrical ‘blanket’ before being transferred onto the print material. It is called ‘offset’ print because rather than directly transferring the design from the plates to the stock material, the design is first offset onto a middleman of sorts – the rubber blanket.

The Offset Printing Machine

To perform offset print on your stock materials, you will need an offset printing machine, oil-based (water-repellent) inks, and water. The offset print machine has three components – cylinders. These cylinders, also called rollers, are – the plate cylinder, offset blanket cylinder, and print or impression cylinder.

In the market, there are many brands of offset print machines, however, among them, the famous ones are HEIDELBERG, KOENIG & BAUER, KOMORI, and ManRoland.

Plate Cylinder

The plate cylinder holds the metal plate on which the image or design to be printed is etched. These plates are usually thin, flexible, and more prominent in size than the stock material being printed on. They are usually made of aluminum, although plastic or polyester are used to make plates for small-scale and medium-quality jobs.

Offset Blanket Cylinder

The blanket cylinder holds the rubber material on which the etched design is first offset before finally being transferred to the print material. Initially, when the offset print technique was first discovered, specially treated cardboard was used as the blanket and thus draped around the offset blanket cylinder. Rubber proved to be a more viable and functional option and has since been adopted as the widely-accepted blanket material.

Print/Impression Cylinder

The print cylinder carries the stock material that is being printed on. This is usually paper, but offset printing can also be done on wood, canvas, or cloth. This print cylinder brings the material to be printed on in contact with the blanket cylinder.

The Process - How Offset Printing is Done

- First, the etched metal plates (known as CTP plates) are treated such that only the image and design etchings attract ink; the other parts of the plate repel ink. This is done by applying a thin water film on the non-image parts of the plate, making it unable to attract the oil-based inks, which are water-repellent.

- The etched metal plates are then loaded around the thin plate cylinder.

- As the machine starts, all the cylinder rollers start spinning. The plate cylinder comes in contact with the rollers applying ink. The ink sticks to the etched image on the plate, and the water on the other part repels the ink.

- The offset blanket cylinder and the plate cylinder roll in opposite directions. When they eventually come in contact, the ink is transferred to the rubber blanket, thus creating a duplicate of the image design.

- The print cylinder also rolls in the opposite direction to the blanket cylinder. And when they come in contact, the inked duplicate image on the rubber blanket is transferred onto the print material. This completes the offset print process.

Types of Offset Printing

There are two main types of offset print: web-fed offset printing and sheet-fed offset printing.

Web-fed Offset Printing

Web-fed offset print involves feeding a large continuous roll (web) of paper (or any other print material) through the offset print machine. This method is often used for very voluminous large-scale printing jobs that require a large number of print copies to be produced – jobs that require over five to ten thousand copies. Newspapers, magazines, and sometimes packaging boxes are produced using web-fed offset print presses. The rolls are cut, by another part of the printing machine, into individual units after they have been printed upon to produce numeral identical copy units.

There are two types of web-fed offset print – heat-set web offset and cold-set web offset.

#1. Heat-set Web Offset Print

This is a type of web-fed offset printing whereby the print ink is dried by passing the freshly printed rolls through a heated drying chamber positioned immediately after the printing press units.

#2. Cold-set Web Offset Print

This type of web offset printing is typically used for lower-quality printing jobs. Here, the ink dries eventually by absorption into the underlying print material. This method is often used in newspaper production. It is a very cost-effective option, especially when compared with the heat-set web offset printing type.

Advantages of Web-fed Offset Print

#1. Fast Production Speeds

Most web-fed offset printing presses can print up to 3000 copies per minute, resulting in huge production print volumes in a relatively short time.

#2. Cost Effective

Huge rolls of paper are usually very cheap compared to bundles of precut paper. Thus web printing reduces production costs by utilizing these huge cheap rolls. Very cheap, thin, low-weight stock paper can also be accepted by web-fed offset printing presses, making them very cost-effective and budget-friendly.

#3. High and Consistent Print Quality

Once a roll of paper is fed to a web offset printing machine, it rapidly works relentlessly, duplicating the print designs until the roll is exhausted or the machine is stopped. This means the automated and relentless printing means the print outlook and quality remain consistent for all copies printed. And because the level of human interference needed is minimal, there is less chance of error, thus raising the overall quality of the print job.

Disadvantages of Web-fed Offset Printing

Difficult and Expensive to Set Up

While web offset printing presses result in faster production timelines and cheaper production costs, the initial set-up costs are very high. The web offset printing machines are huge and require a large production space. This raises the initial production costs. This is why web-fed offset is ideal for voluminous printing jobs.

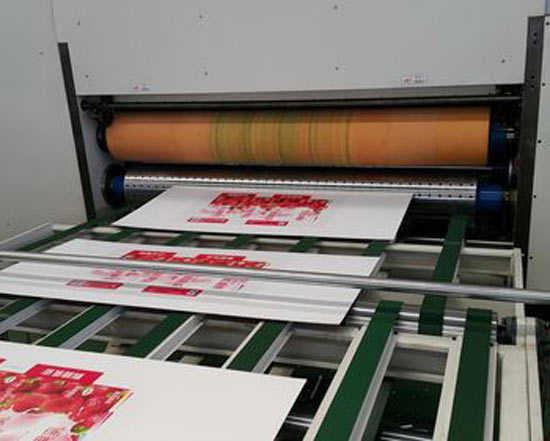

Sheet-fed Offset Printing

Sheet-fed offset printing involves feeding the printing machine already cut individual sheets of paper, usually done manually via a suction bar that lifts and drops each sheet into place. It is often more labor-intensive and time-consuming than web-fed printing presses, but it is not without its advantages.

Advantages of Sheet-fed Offset Print

#1. Fast and Inexpensive Set-up

Sheet-fed printing presses are not as large as web-fed types; neither is it as expensive nor space-consuming. This makes it fast and affordable to set up.

#2. Small Scale Low-volume Printing Jobs

The cheap and easily set-up sheet-fed printing system is ideal for small-scale businesses or manufacturers with a low volume of recurring tasks. Low production speeds have minimal impact on them as they do not have a huge volume of print jobs.

#3. Optimal for Specialized Custom Request Orders

Sometimes in a run of printing jobs, some particular print copies might require unique print design or finishing. This is very hard to do with web-fed presses as the machine churns thousands of identical copies simultaneously, and you cannot print any unique individual copy. With sheet-fed printers, however, you can do this easily.

Disadvantages of Sheet-fed Printing

– It is not ideal for large-scale high, volume jobs.

– Low production speeds and higher production costs.

For paper packaging boxes, cosmetics packaging, paper tubes, rigid boxes, etc, it’s good to choose the sheet-fed offset printing way. And in our factory, we have ManRoland 900, CD74, etc printing machines. The maximum print size is 2050mm x 1510mm. So your jumbo-sized packaging can be finished in one piece without gluing together.

Offset Print Versus Digital Printing

Digital printing involves using technology and computing processors to transmit images and texts on paper. And given the prevalent unwavering affinity for technology, digital printing is a prevalent printing choice nowadays and has proven to be the main challenge for the offset print technique. We will compare the two popular methods of printing using a few standard printing metrics.

Initial Set Up

Once you have a computer or any electronic gadget and a digital printer( which could be an inkjet or laser), you can start printing immediately. These gadgets are easily accessible and affordable. Offset printing machines, however, are usually very large and expensive. So for most domestic and small-scale printing tasks, many people choose digital printing.

Production Turnaround Time

The print item comes off a digital printer instantly and is ready for use immediately; this means minimal production turnaround. This is less so for offset printers, which, in addition to the initial set-up time, have to dry the printed ink after printing. However, this seeming speed advantage of digital printing disappears as the job volume increases. For larger tasks, offset print is much faster because, after the initial set-up, the machine does the printing at a fast rate. This highlights another difference between the two methods of printing – digital printing is best for small, primarily domestic, printing jobs; offset printing is ideal for commercial purposes.

Print Colors and Quality

Digital printers are mostly limited to printing in black and white and the CMYK color palette. Offset print offers a broader range of color production alongside vivid and detailed design replications. You can only achieve highly accurate true-life color schemes like Pantone and HKS with offset printing. In our company, we have been in the offset print business for over 20 years, and have made thousands of packaging boxes for our customers.

Conclusion

The offset printing technique has been around as early as the 1900s. Its long-lasting, high-quality, and relatively cheap printing results mean it remains a popular printing choice to this day. It is widely applied to print newspapers, magazines, book jackets, rigid boxes, corrugated boxes, folding cartons, and other print items. In this article, we have explained the intricacies of the offset print technique, and we hope you are now armed with adequate information to make the right printing choice for your next project.

As a leading packaging box manufacturer in China, UNICO can manufacture the box with your custom design offset printing, including corrugated boxes, cardboard boxes, rigid boxes, puzzles, card printing, etc. Welcome to contact us for free quotes.