An Overview of Hot Stamping

Hot stamping also called foil stamping or foil print, is a printing process whereby metal foil designs or pre-dried ink are transferred onto a surface using image molds or stamping dies at very high temperatures. It emanated from an ancient process adopted by early calligraphers – where they use heat to apply raw gold leaf to paper, a process combined with embossing to leave a raised imprint on the paper’s surface. Then, it was a costly way of finishing print materials. Thus, it was associated with luxury and wealth. Hot stamping now is not that expensive, as other metal elements are used as a foil in place of gold, and dried ink is also used in some cases. You can choose hot stamping to various surfaces, including paper, plastic, leather, rubber, or fabric

Tools Used for Hot Stamping

There are three main items in hot stamping – the paper (or other stock material you want to hot-stamp), the die, and the foil.

Paper

This is the first item required for the process of hot stamping. Before you can do anything, you need to have a surface material to which you plan to apply the foil stamp. This material is often paper or cardboard, but it could also be plastic, leather, or rubber.

Die

You may also know it as the “hot stamping plate”. This is where the design to be stamped on the material is etched. It may be shaped directly to replicate the design, or it may be cast. Usually, the die is created based on the type and pattern of foil used. This, plus budget and application, inform the type of metal used to make the die. There are three common metals used – magnesium, copper, and brass. Some dies are, however, not made from metal but instead steel or rubber.

#1. Magnesium Hot Stamping Die

This is the inexpensive low-budget type of metal die. It is made from magnesium, a relatively soft metal. Magnesium dies are lightweight, easily molded, heat up quickly, and need little time to finish etching. While it is cheaper, it is not durable as it breaks faster than the other types of metal dies.

#2. Copper Hot Stamping Die

Copper dies are regarded as one of the most effective metal dies. They are typically strong and very durable, sometimes lasting up to a million foiling machine cycles – which is a lot, especially when compared with magnesium dies which are typically capable of just a few thousand cycles. This strength and durability mean copper dies are sturdy and heavy and take time for designs to etch. It also means they can generate detailed, high-quality designs that would last a long time.

#3. Brass Hot Stamping Die

These are the most expensive and durable of the three metal dies. Brass hot stamping die produces high-quality designs renowned for their high degree of artistry and precision.

#4. Steel or Rubber Hot Stamping Die

These are less popular types of dies reserved for specialized uses. Rubber dies are used when it is essential to minimize distortion around the stamped area, and they are mainly applied on plastic or rugged acrylic surfaces. Steel dies, made of hardened steel, are sometimes even more durable than metal and are adopted for very long and intensive production runs.

Foil

Foils are the multilayered coating that is transferred to the material’s surface. They come in various colors and textures, typically categorized into five types – metallic, pigment, scratch-off, pearl, and holographic foils.

#1. Metallic Foil

This is the most commonly used type of foil as it typically replicates the look of popular precious metals like gold, silver, bronze, and copper. This foil type can also replicate metallic colors if you want a colorful surface finish.

#2. Pigment Foil

Pigment foils have no metallic sheen but are used to produce a range of matte and gloss-colored surfaces. They are typically used to create a subtle design color contrast on plastic or paper.

#3. Scratch-off Foil

This is a functional foil type used on lottery tickets and recharge cards. They are ideal for temporarily hiding sensitive or redacted information. They are made to be temporary and easily scratched off.

#4. Pearl Foil

Pearl foils are translucent foil types that add a pearlescent shine to colored surfaces. They are ideal for elegant and formal print items like invitation cards or business cards.

#5. Holographic Foil

These are used to replicate a dazzling rainbow effect on print surfaces, reflecting various colors at the viewer when exposed to light.

The Hot Stamping Process

Hot stamping can be done manually using a manual machine like clamshell presses or mechanically using a commercial foiling machine like straight stamp presses or roller presses. Manual machines are only ideal for low-volume jobs. For commercial industrial-scale jobs, however, it is imperative to use a mechanical foil stamping machine.

The basic steps for hot stamping materials remain consistent regardless of the machine type.

- First, the preferred design is etched on a die. Typically, acid etching is used – a process whereby the die is placed in an acid solution after exposure to ultraviolet light.

- The material to be stamped is placed on a flat plate. Then, the foil is placed between it and the die.

- The die is heated to a very high degree and pressed onto the material. The heated die activates the glue in the foil and presses it into shape on the print material.

- The die is then removed, and the foil stamping process is complete.

Applications of Hot/Foil Stamping

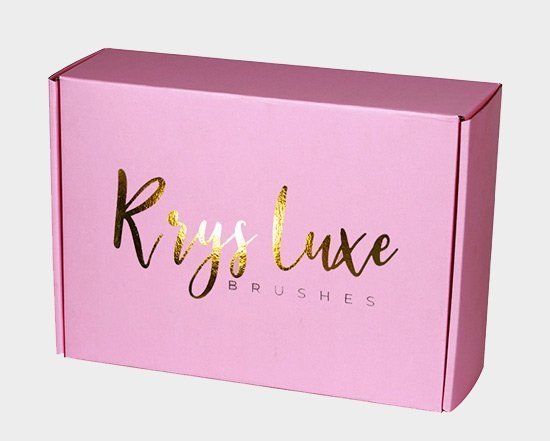

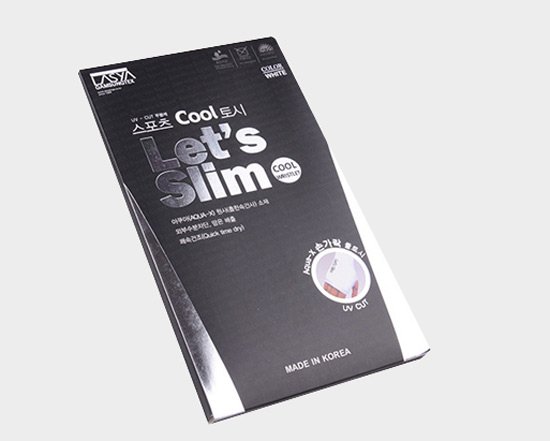

Hot stamping is applied in the packaging industry to add a luxurious and premium aesthetic to their packaging box design. The brand or product name can be stamped with gold foil, making the overall package more attractive and alluring, including cosmetic boxes, electronic boxes, perfume boxes, etc.

You can also choose to use hot stamping in advertising for branding and promotional campaigns. Attractive metal or pigment foils can be stamped on brochures or catalogs to make them even more enticing. Scratch-off foils can also be used for scratch and discard lottery campaign tickets.

In business for embossing business stationery like letterheads, business cards, envelopes, and even business proposal reports, it’s available to use hot stamping.

Hot stamping can also be applied in industries and financial institutions to protect against counterfeiting. Custom-made holographic foils can be used to validate genuine documents or products to deter the production of fake duplicates.

Things to Consider Before Foil Stamping a Product

The Material Type

Understanding the specific needs and requirements of the material you plan to stamp foil on is essential. Paper, plastic, rubber, and leather all have different properties. Thus, the type of die, the foil used, and the stamping technique applied would all have to be unique to the particular type of material to achieve optimal results.

The Design Fonts and Lettering

The smaller the font and lettering are, the less ideal it is to hot stamp foils on them. Hot stamping does not allow for small intricate designs without losing quality and definition. So if you want to stamp foils on your design, go big. It is also important to consider the design color scheme before starting the foil stamping process. Your preferred choice of colors will inform the type of foil to use and which metallic color to add.

Production Budget

Like any other manufacturing undertaking, it is essential to consider your budget and identify your financial restraints. This would help you identify the ideal die and foil type for you.

Advantages of Hot Stamping

Durability

Perhaps the most significant advantage of hot stamping is its longevity, especially when compared with another kind of imprinting, which uses ink primarily. Ink prints usually fade and smudge over time, harming their life cycle. On the other hand, foil stamps are imprinted with heat, making them resistant to smudge, fading, and even moisture.

Clean and Effective Application Process

The heated die is pressed down on the material’s surface, and out comes your beautiful stamped foil design; no messy mixing of inks or spilling of paint.

Versatility

Hot stamping can be used for various materials – paper, fabric, leather, rubber, plastic, etc. this range of applications is one of the significant benefits of hot stamping. It also offers a wide range of eye-catching metallic colors from which you can choose best suited to your branding and packaging needs.

Luxurious and High-quality Aesthetic

To put it simply, hot stamping makes your product look very premium and luxurious. It thus enhances the perceived value of the product when it comes across to prospective viewers as very high-class and expensive.

Conclusion

There are many options for the choice of finishing to apply to your print items and other materials. Foil print is the unique and most appealing option. Not only does the metallic sheen add to its visual appeal, but the tactile quality that the process produces on stamped materials would also make your product satisfyingly stimulating to hold and touch. Whether it is business stationeries, wedding invitations, or even promotional brochures, you’d want to communicate quality and luxury to whoever your target audience is. This is why hot stamping is the ideal choice for you.